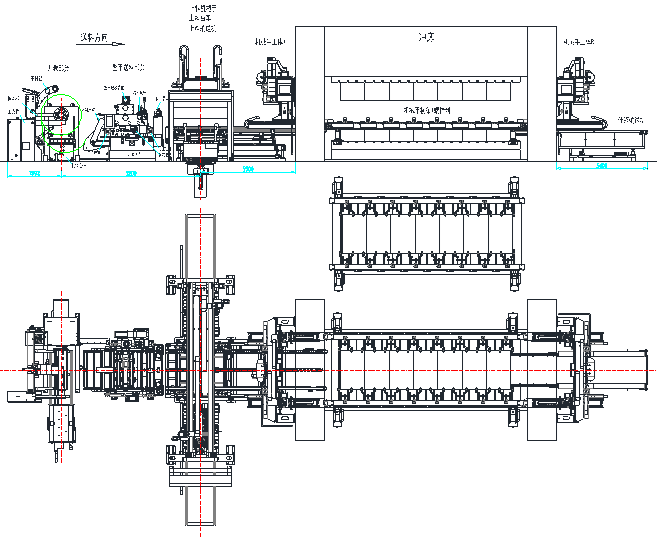

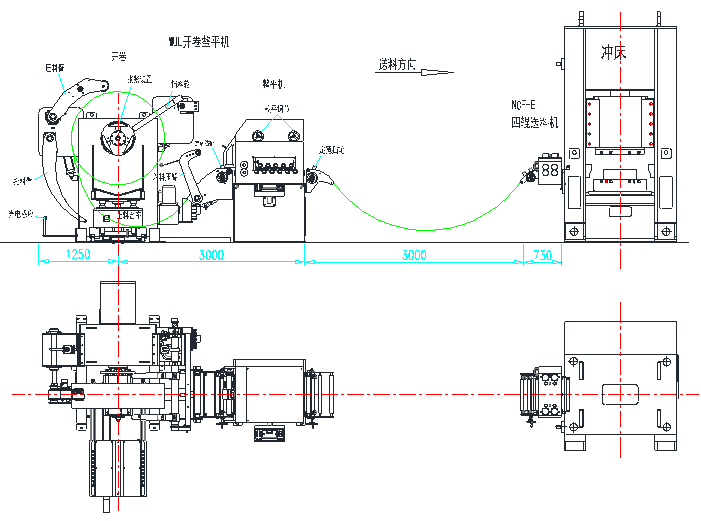

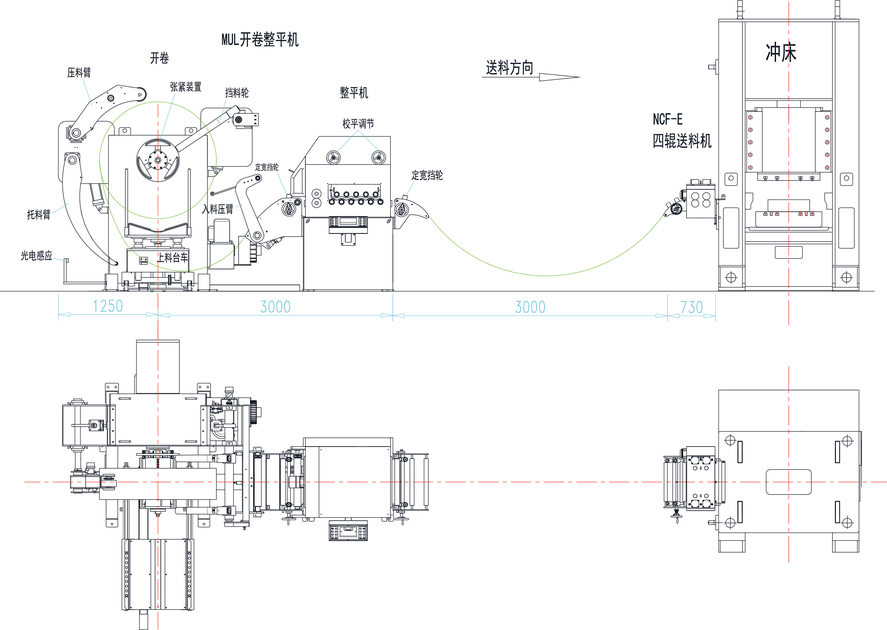

This precision roller leveling and feeding machine (3-in-1) perfectly meets the mold testing needs of mold manufacturers, satisfying the mold industry, especially automotive parts mold manufacturers’ needs for full-size, high-strength material trial production. It is an ideal platform for verifying and debugging the performance of various transfer molds, progressive molds, and single-engineering molds. During the mold testing process, the equipment, with its high repeatability and flexible feeding pitch settings, can quickly and accurately match the process requirements of different molds, effectively assisting in verifying the stamping stability, pitch accuracy, and forming effect of the mold.