This NC precision roller feeder (3-in-1 type) is specifically designed for automated stamping of medium and heavy plates in furniture hardware, office furniture, and home décor components. It is suitable for the mass production of diverse products such as sofa and chair frames and casters, table and chair legs, storage cabinet hardware, drawer slides, bed frame connectors, hinges, shelf brackets, decorative handles, lighting metal parts, and kitchen and bathroom hardware accessories.

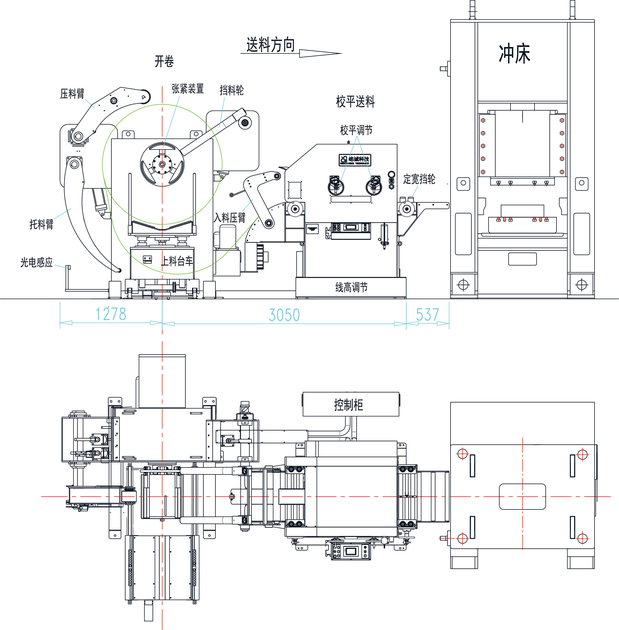

Addressing the characteristics of furniture hardware in the furniture industry, such as numerous specifications, diverse structures, high load-bearing strength requirements, and fine surface treatment, this machine innovatively integrates material racking, leveling, and feeding functions. It adopts a high-performance servo drive and intelligent central control system to stably handle various materials such as cold-rolled steel, hot-rolled steel, and stainless steel.

Combined with a high-precision in-mold robotic arm for inter-station transfer and seamless synchronization with the stamping machine, it ensures high efficiency, precision, and automation from blanking to forming, significantly improving the flexible production level and product competitiveness of furniture hardware manufacturing.