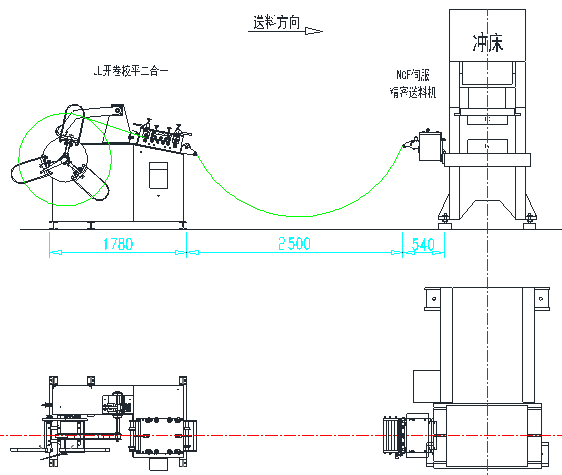

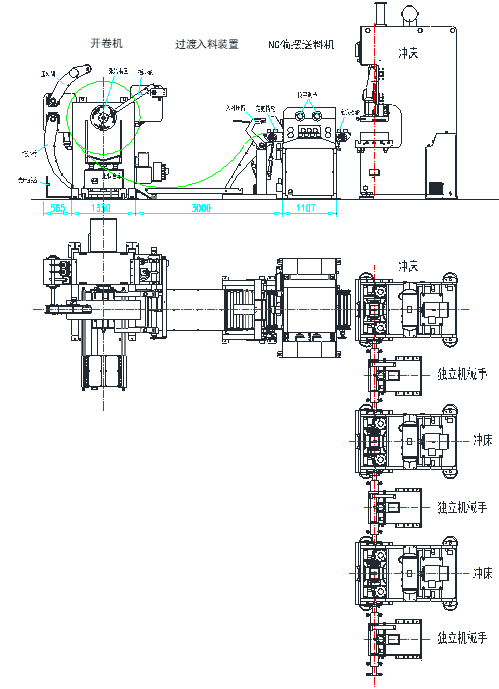

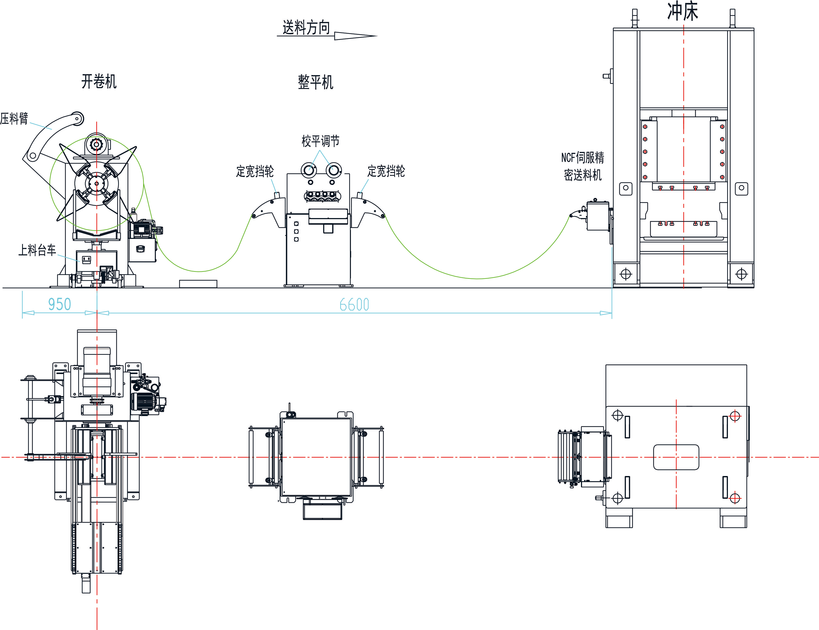

This production line is specifically designed for uncoiling, leveling, and feeding pre-coated sheets, PCM sheets, and embossed aluminum sheets with a thickness of 0.35-0.6mm for refrigerators and freezers. The entire line consists of an uncoiler, an ML precision leveler, and a servo feeding mechanism. The leveling accuracy can reach ≤0.3mm, and the feeding accuracy is ±0.2mm. It can be used in conjunction with downstream shearing machines, conveyor belts, and forming machines to achieve a fully automated process from uncoiling to finished product, ensuring high-efficiency production.