This production line is specifically designed for high-precision metal stamping parts, suitable for the automated production of precision components such as shielding covers, connector springs, contact pieces, grounding terminals, and spring clips.

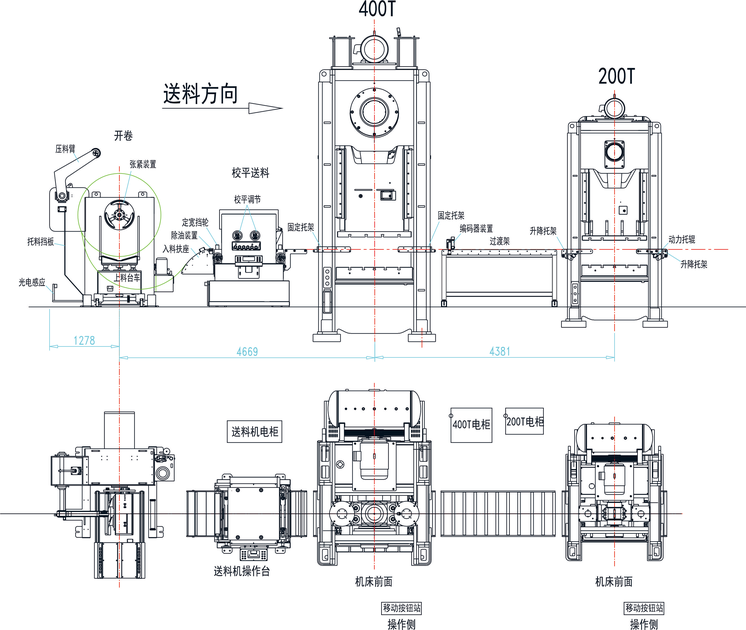

The entire line is highly efficient and reliable: the uncoiling section uses a frequency converter for smooth operation and flexible speed adjustment; the feeding section features a servo drive and four-gear transmission structure, effectively eliminating transmission backlash and ensuring high feeding accuracy and fast response.

Compared to common three-in-one feeders, this production line offers a simpler structure, easier maintenance, and lower overall cost while maintaining the same precision, making it an ideal choice for small to medium-sized precision stamping production.