This production line is specifically designed for power transformer heat sinks, specifically silicon-free thermal conductive sheets. These products typically require thin materials, high surface quality, high precision, and high production volume.

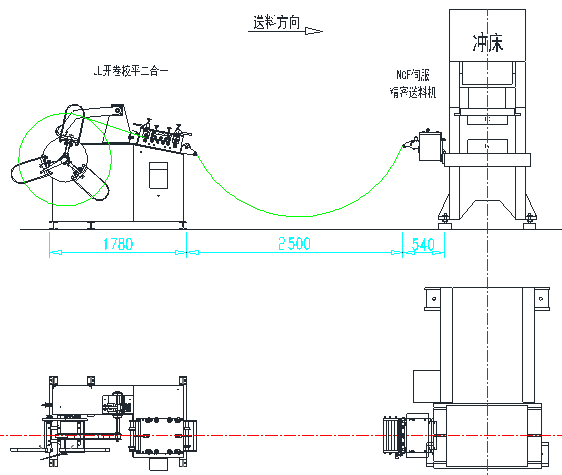

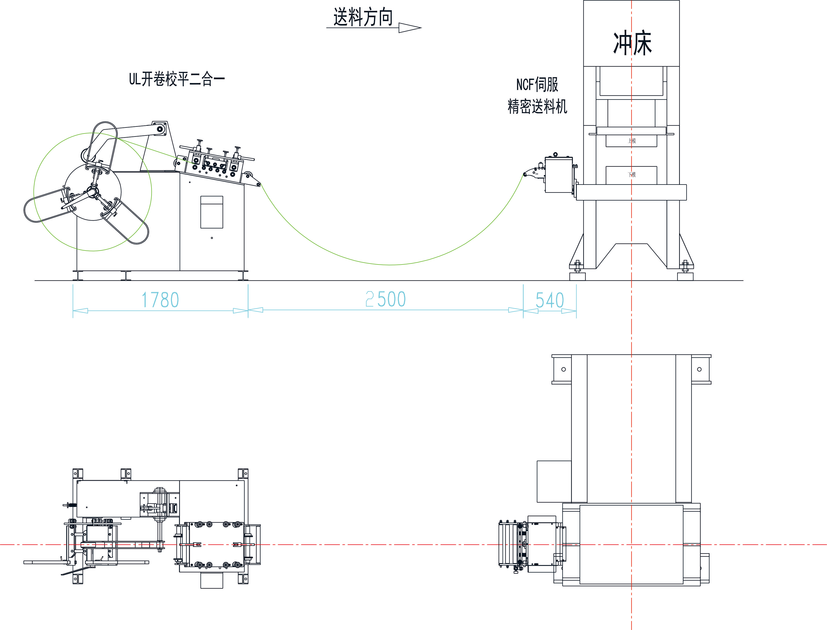

The uncoiler controls the tension (hydraulic) and rotation (variable frequency motor) of the coil and is equipped with sensors for coil presence/absence detection, coil rotation start detection, and coil rotation stop detection, enabling automatic start/stop of the coil and automatic shutdown when the coil is empty.

The leveling machine is equipped with material detection sensors to detect when the strip tail passes through, controlling the stamping line to stop in time. It also has a sag detection sensor to detect material buffer level and control the step feeding requirements of the servo feeder. The servo feeding unit controls the continuous step feeding of the strip, ensuring feeding accuracy and achieving efficient mass production.