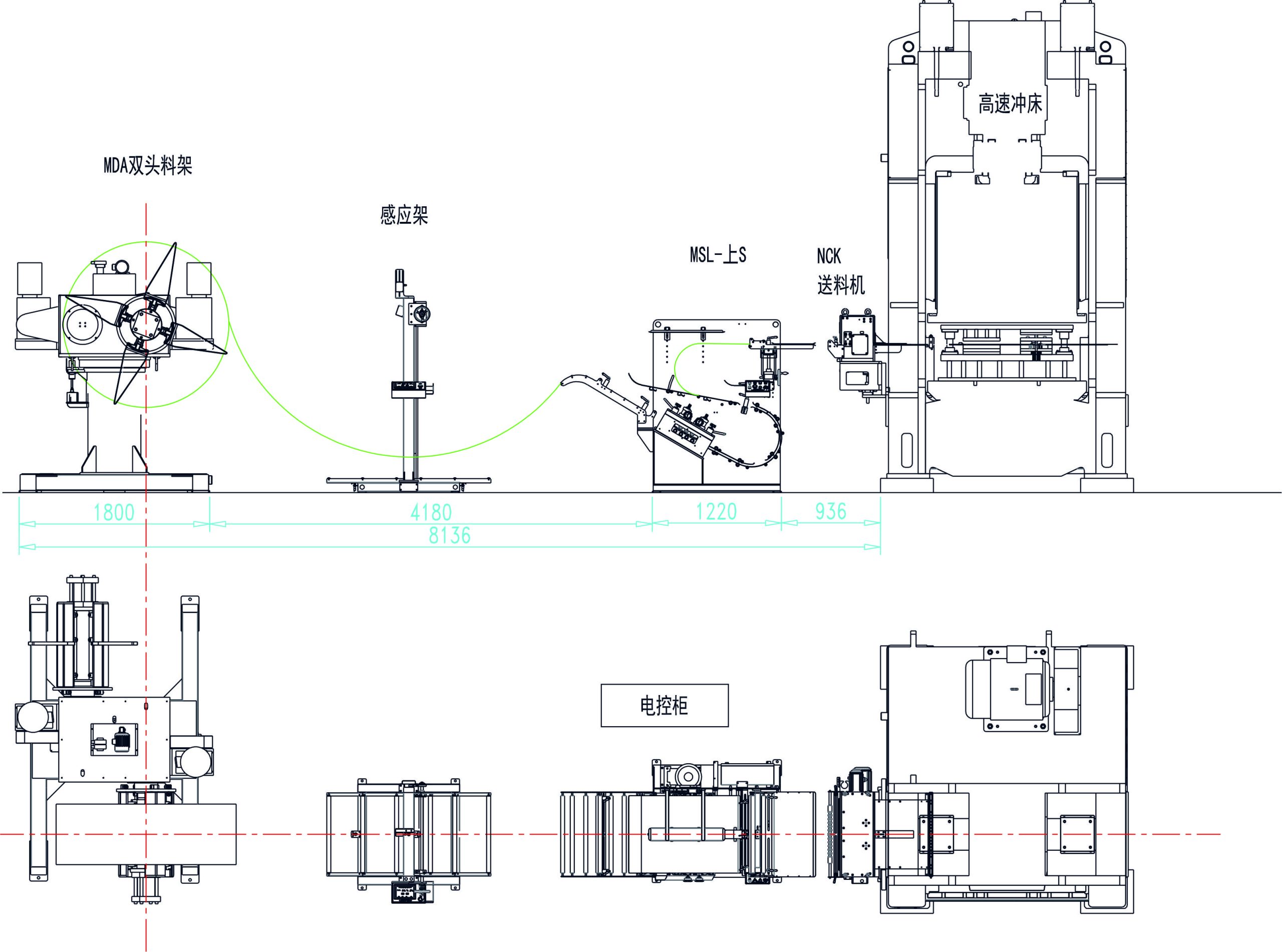

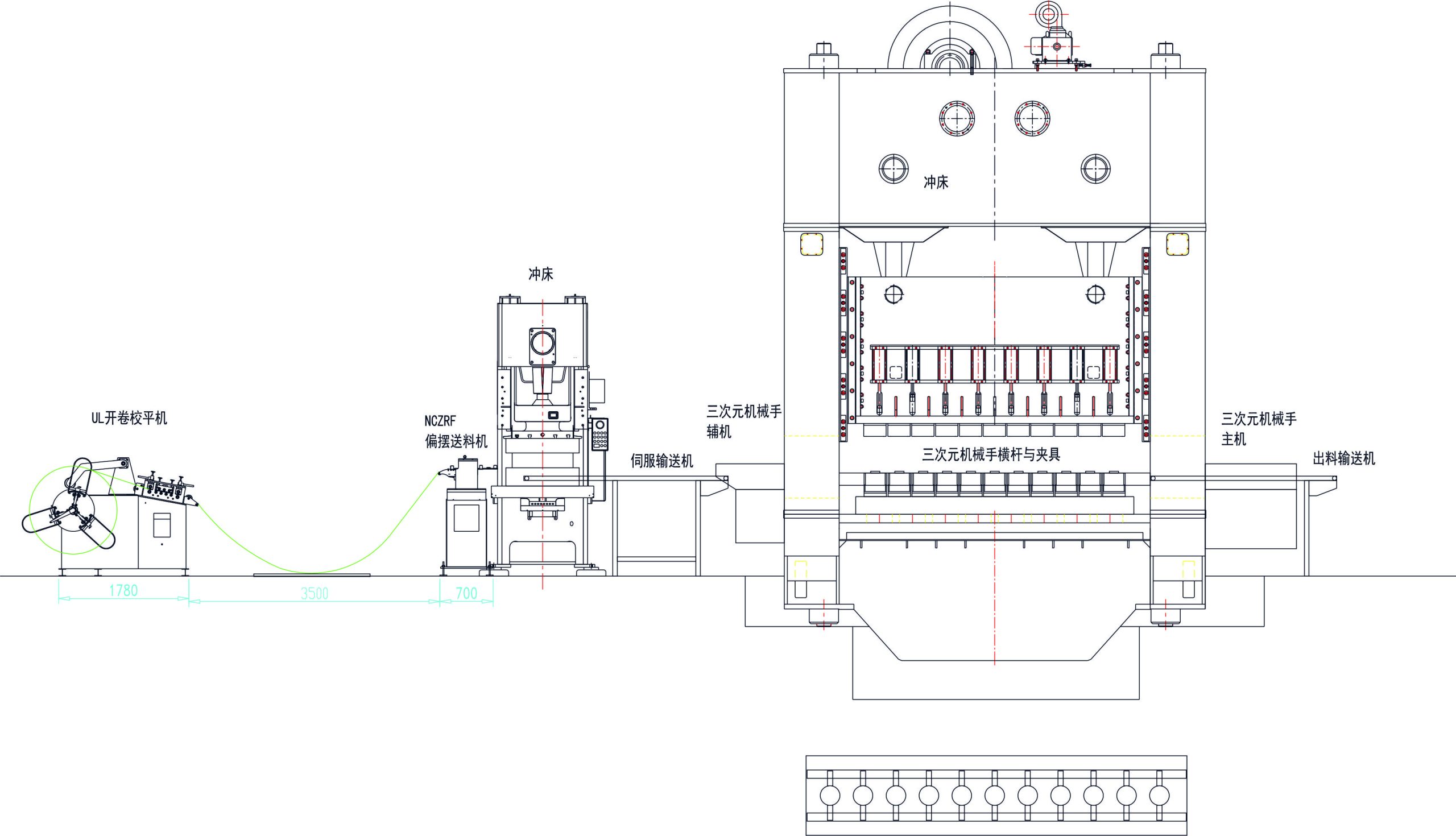

Motor housing feeding production line

This automated feeding production line can be used for the automated stamping production of various motor housings, end caps, etc., and is also widely used in the manufacturing of precision components such as cast aluminum rotors and aluminum-cased external rotor motors.

The production line consists of a two-in-one uncoiling and leveling machine + a swivel feeder + a servo conveyor belt + a three-dimensional conveyor robot + an output conveyor belt. After the material coil is leveled by the two-in-one uncoiling and leveling machine, it is fed to the previous punch press by the NC swivel servo feeder. The material is unloaded by the die inside the punch press. The servo conveyor receives the material under the previous punch press and conveys it to the next punch press, connecting with the three-dimensional conveyor robot. The three-dimensional robot robot works with the punch press to gradually transfer and complete the stamping process through 12 steps, including unloading, punching, and stretching. Finally, the product is conveyed out by the conveyor belt. Since the speeds of the front and rear punch presses cannot be completely synchronized, this process focuses on handling the transition synchronization between the two machines from both a control and structural perspective.