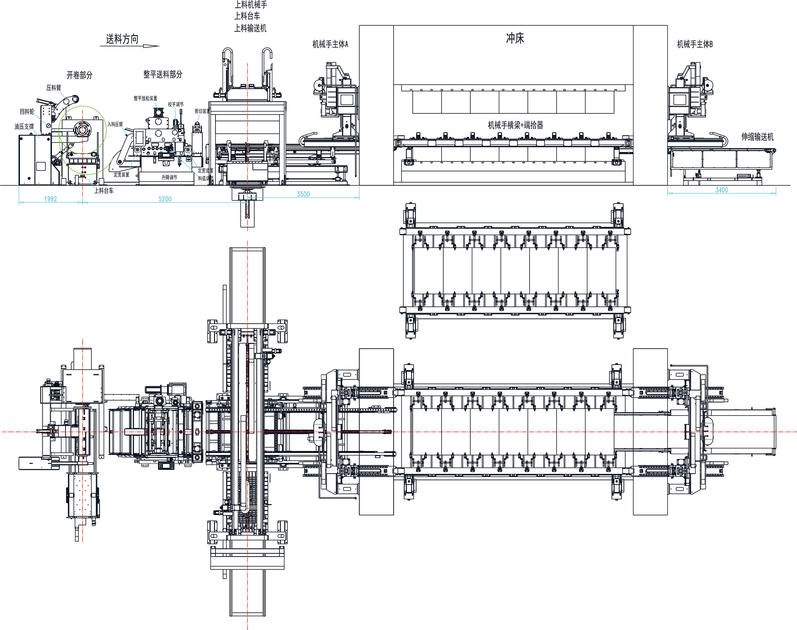

This production line consists of a three-in-one feeder and a two-dimensional robotic arm, suitable for the automated production of components such as car doors, hoods, fenders, trunk lids, roofs, A/B pillars, longitudinal beams, wheel arches, bumpers, seat frames, and chassis structural parts. Automotive stamping parts are generally characterized by high material strength, complex shapes, large dimensions, and stringent requirements for appearance quality and assembly precision, demanding extremely high production continuity and stability.

Addressing the automotive industry’s demand for high-efficiency and high-stability production, this machine integrates material racking, straightening, and feeding, employing servo drive and central synchronous control to effectively handle high-strength steel plates and aluminum alloy materials. It is also equipped with an in-mold robotic arm for conveying, synchronized with the stamping press, achieving highly efficient automated stamping.