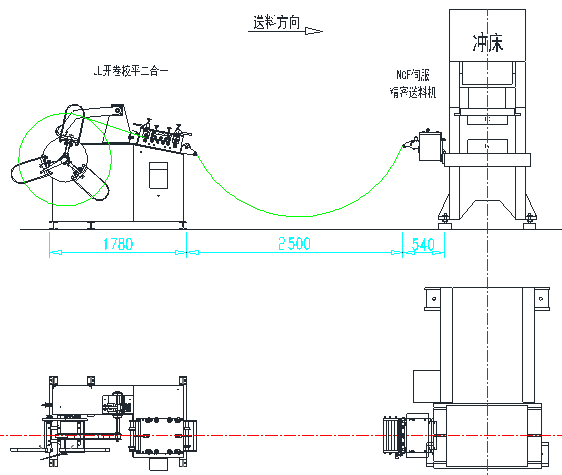

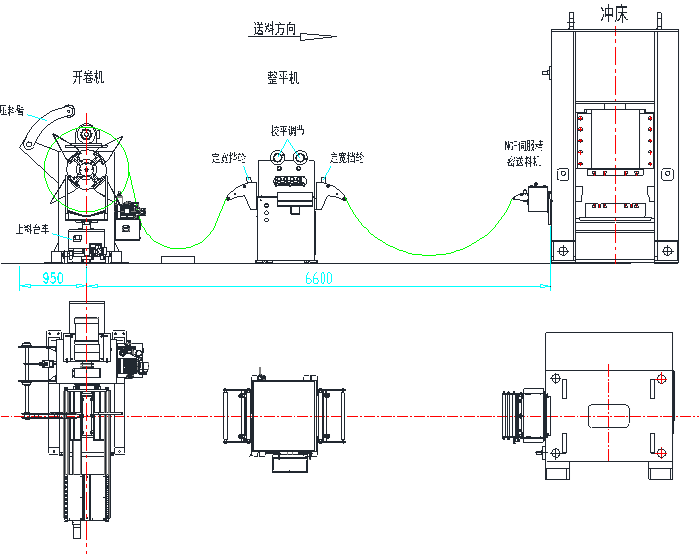

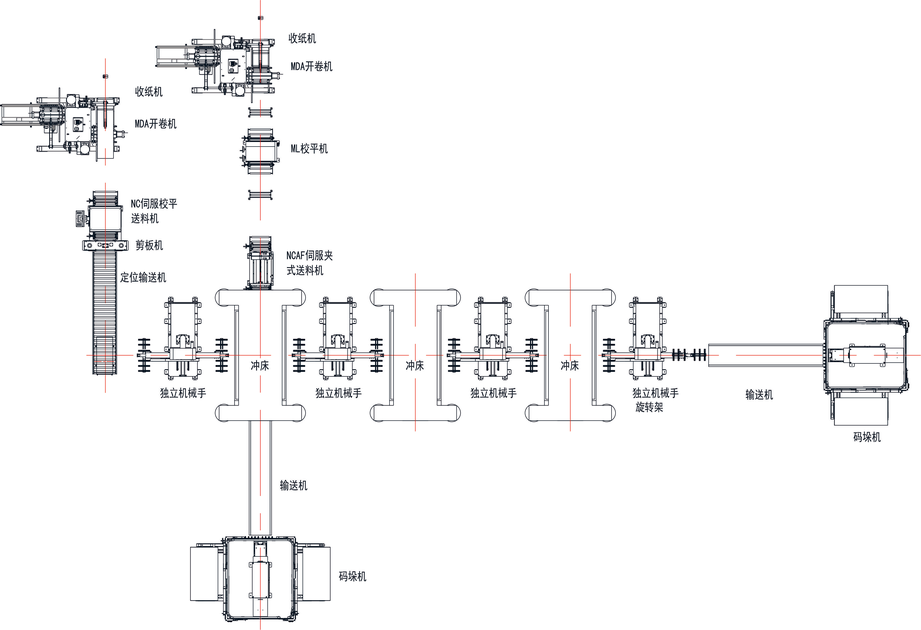

This production line consists of an AT uncoiler, an NCZRF oscillating feeder, and a three-dimensional robotic arm. It adopts a dual-axis alternating feeding system, which is suitable for various arrangements. The CNC operation is simple and saves on the cost of coiled material compared to traditional feeding and uncoiling machines. Its automated operation process, from coiled material feeding, uncoiling, automatic oscillating feeding and punching, to in-mold transfer to finished product output by a multi-station robotic arm, realizes a fully automated process from uncoiling to finished product, ensuring high-efficiency production.