This NC precision three-in-one feeder is specifically designed for the automated production of mine support and building structural components. It is suitable for the large-scale manufacturing of diverse products such as anchor bolt trays, anchor cable trays, W-shaped steel strips, grid-type support pads, mine support beam connectors, protective netting fixing bases, and scaffolding fasteners.

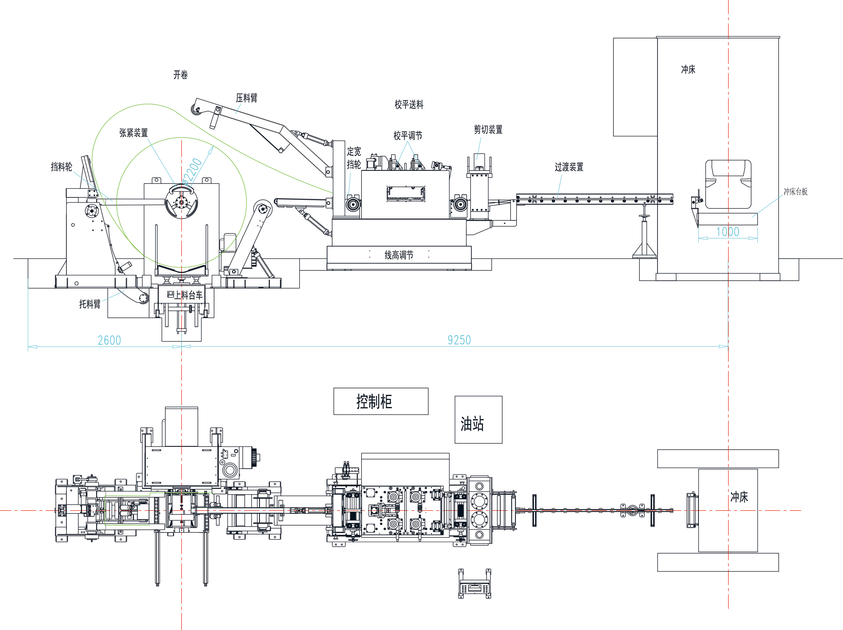

Addressing the characteristics of thick materials and high load-bearing strength in mining and construction industries, this machine is equipped with a manual material stop device and a disc-type material stop width fixing device. Utilizing a high-performance servo drive and PLC intelligent control system, combined with a hydraulic shearing device, it can achieve one-time uncoiling, straightening, punching, and shearing of materials up to 20mm thick.

It can also be used in conjunction with an automatic palletizer to effectively ensure the reliability and production efficiency of mine support systems and building steel structural components.