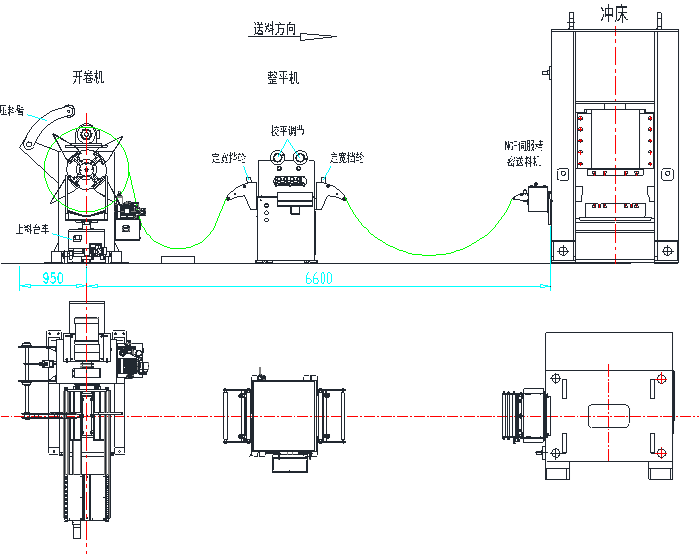

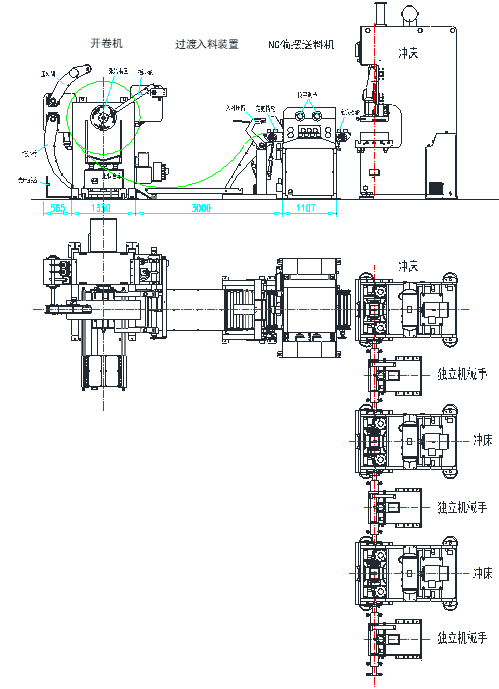

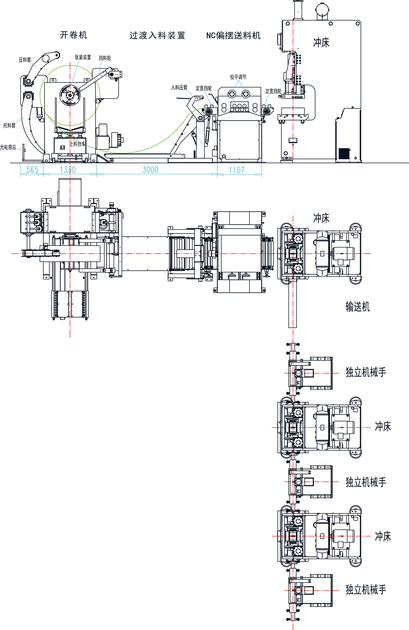

This production line is a highly automated stamping production system specifically designed for processing sheet metal for key components such as washing machine impellers and drums. The entire line consists of an MDA dual-head material rack, an ML precision leveling machine, a servo clamping feeder, a three-in-one die head, and a three-dimensional robotic arm working together. It achieves a fully automated process from roll material loading, precision leveling, servo feeding, to multi-step stamping and forming and finished product handling, ensuring high production efficiency and high product precision.