motor stator and rotor

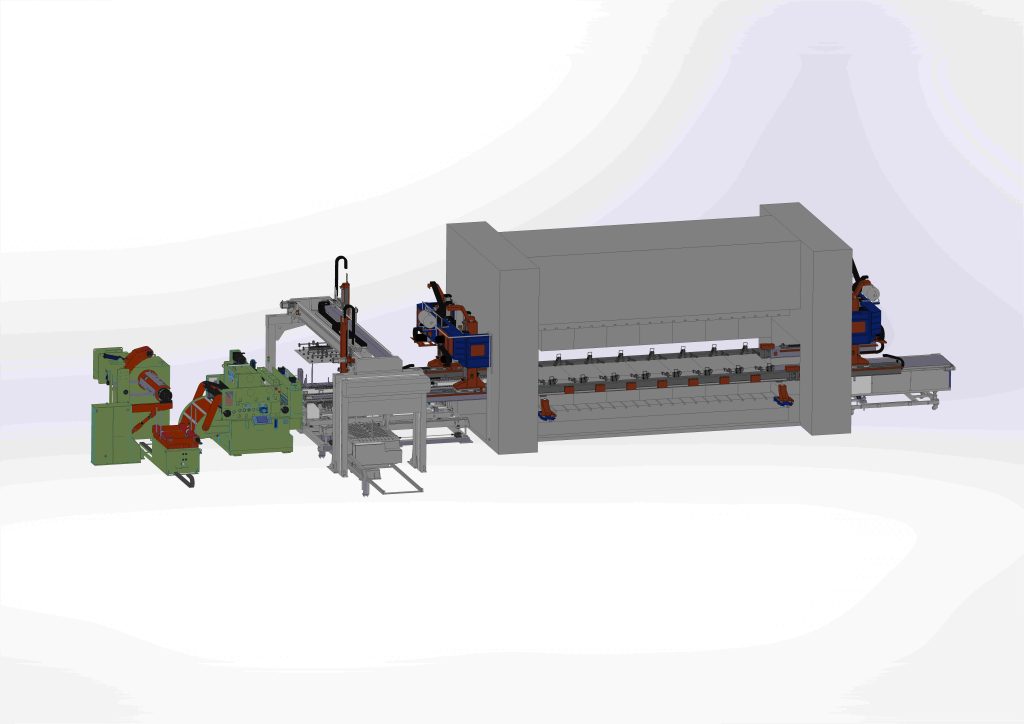

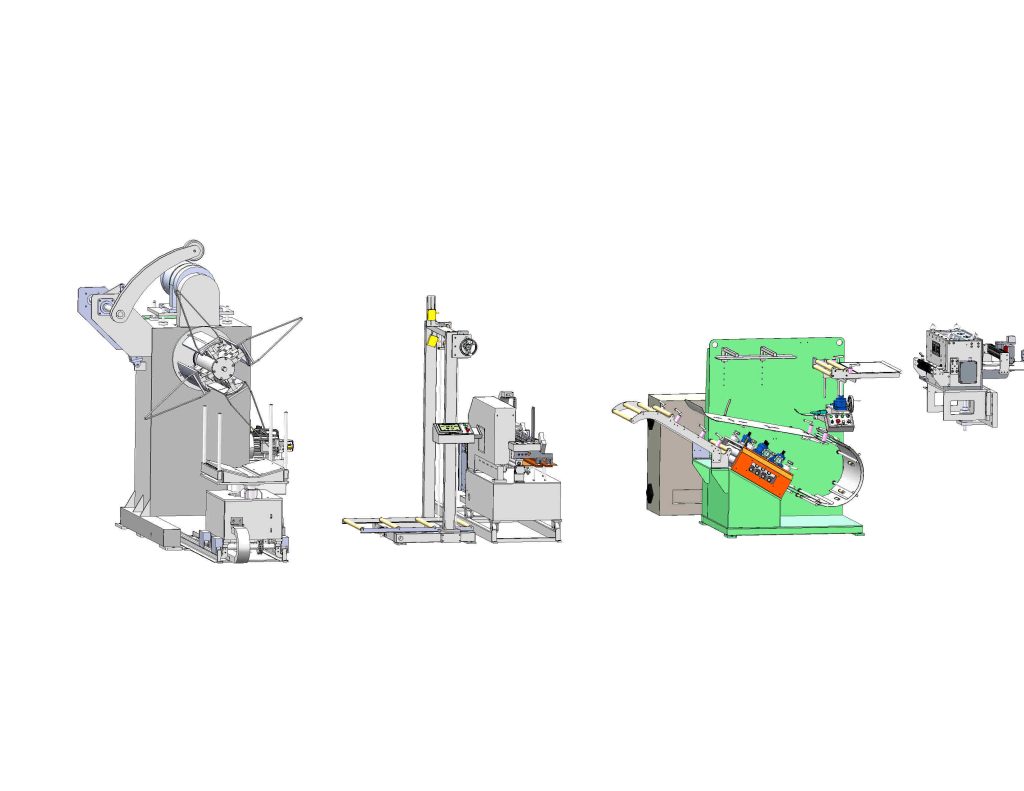

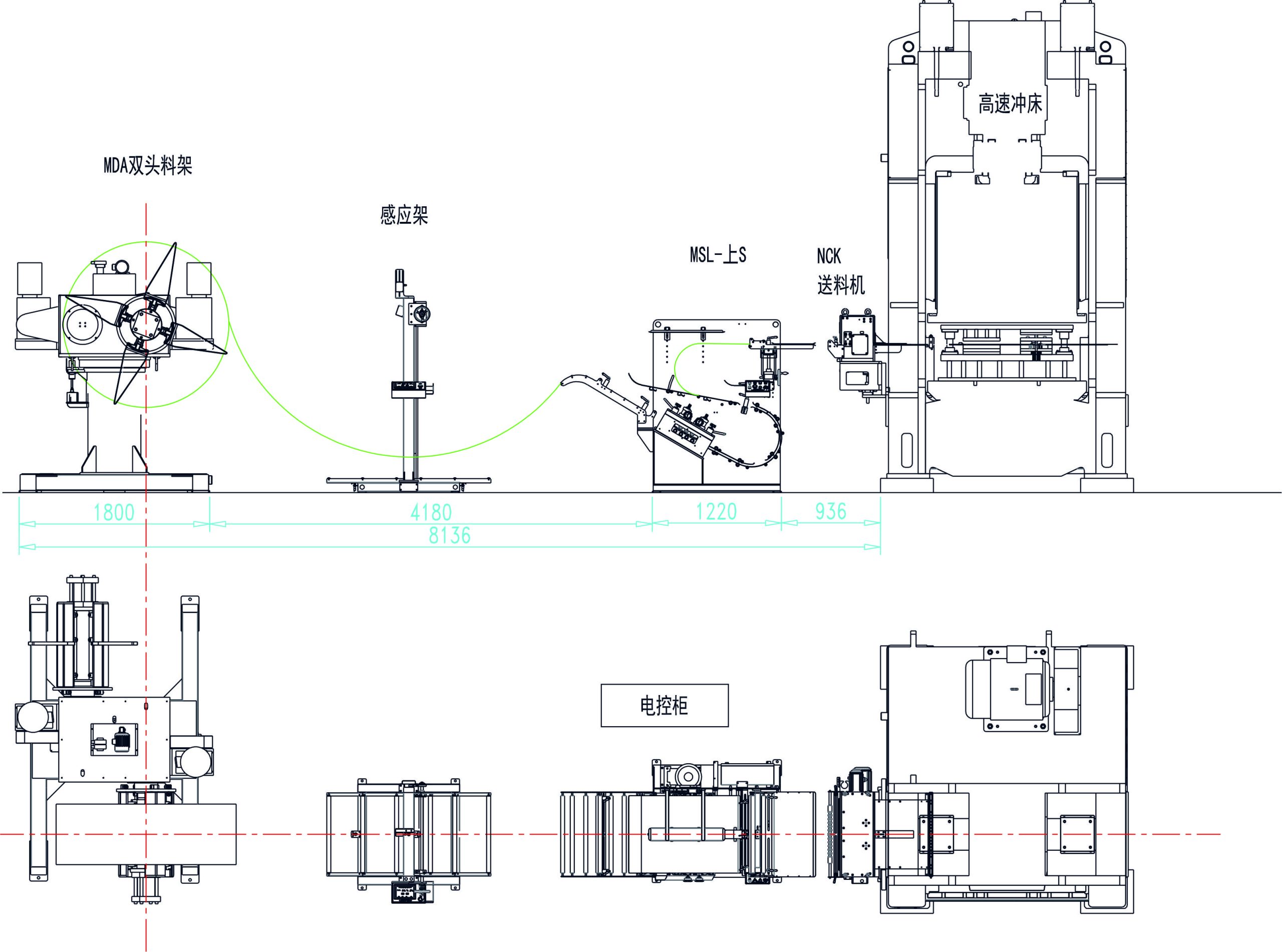

This production line consists of a double-headed material rack, a gantry-type induction rack, an S-shaped straightener, and a dual-servo high-speed feeder. It is commonly used for high-speed, precision stamping production of core components in the motor, new energy, and home appliance industries, including motor cores, stator and rotor laminations, silicon steel sheets, electrical connectors, and micro-motor brackets. These products are generally characterized by thin material thickness, fast stamping pace, high stacking accuracy requirements, and strict burr control, placing extreme demands on production cycle stability and positioning consistency.

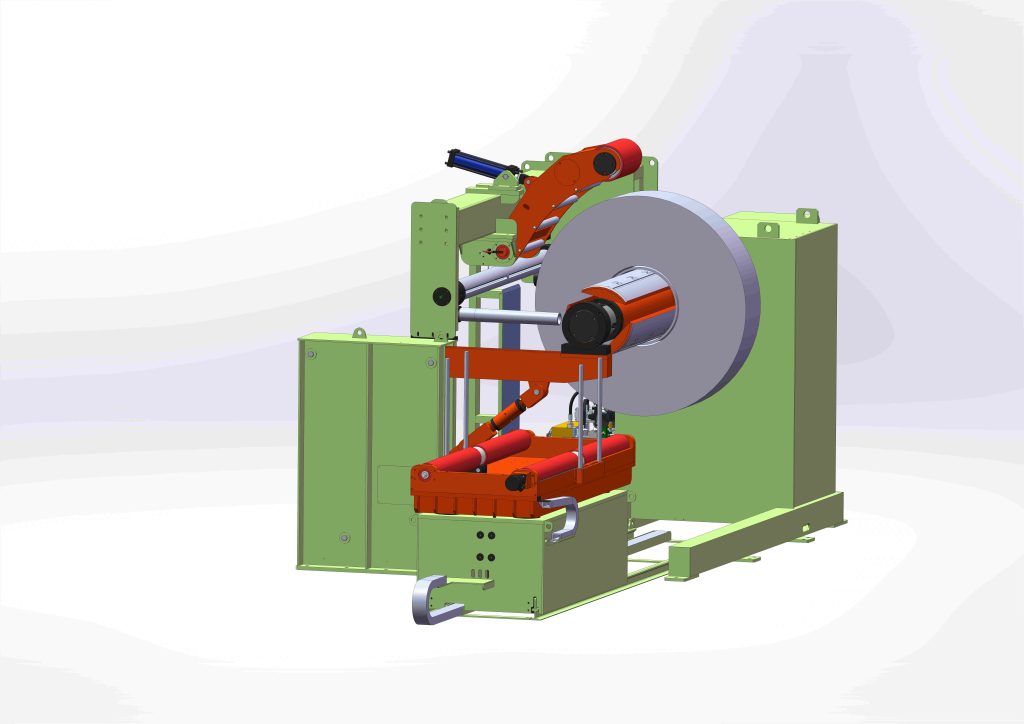

Addressing the high-speed, high-precision process requirements of the motor industry, this series of dual-servo high-speed feeders employs an independent servo control system driven by a precision four-gear transmission. This effectively eliminates material deviation, achieving a feeding repeatability accuracy of ±0.02mm, with a maximum feeding speed of up to 60 meters per minute, significantly reducing accuracy fluctuations caused by equipment inertia.